Air Brakes use an air compressor to compress air into air storage tanks and activate the brakes. The actual brake pad or system is not entirely different from other hydraulic fluid brake systems, but the way the brakes are activated with air pressure is.

Air brakes are used exclusively in large vehicles and especially those that need to carry a lot of weight/freight. This article will give you everything you need to know about how do air brakes work.

Jump To

What are Air Brakes?

In reality, air brakes are not a different kind of brake system from what is found on smaller cars, motorbikes, and ATVs. The difference is in the way the system is actuated by air pressure instead of hydraulic fluid.

In cars, there are drum brake and disc brake systems which are powered by a hydraulic fluid (oil-based) mechanism.

On larger vehicles with air brakes, the actual brake remains the same (a drum or a disc brake rotor setup) but rather than oil powering the brakes, the air pressure is pumped through the brake lines that connect the pedal to the brake.

How Do They Function?

Trucks, trailers, buses, and all other vehicles that use air brakes have an air compressor mounted in the engine bay that is powered directly by the engine to build the air pressure.

This air compressor draws air from the environment and compresses it into high-pressure air stored in a tank. Some models have a single tank, while others can have multiple tanks of pressurized air.

This pressurized air is used to engage and disengage all the braking mechanisms in the vehicle. It is used to power the emergency brake, the handbrake, and the standard brakes on the vehicle with the brake pedal.

Air Brake System Evolution

Truck air brakes can operate in 2 ways.

There used to be a Direct Air-Brake System (DABS). In the DABS system, the air was held in the pressurized tank and pumped toward the brakes when the brake pedal was pressed.

This pressurized the brake cylinders and caused the brake calipers to move and tighten around the brake disks. The DABS system is very similar to how hydraulic brakes work and operate on cars now.

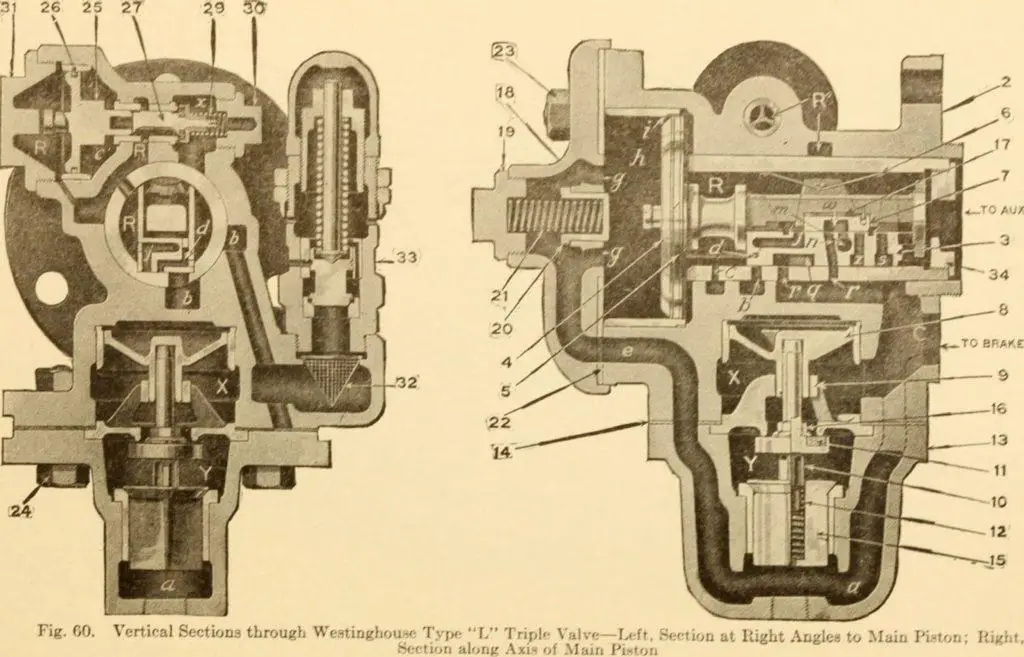

There is also the Triple Valve mechanism (sometimes known as the Westinghouse system), which was developed by George Westinghouse in 1869. It works the opposite way to the DABS system.

In the Triple Valve system, the brake calipers are completely contracted around the brake pads in their natural position (or when the pressure is low) and when high-pressure air is pumped into the system, it lifts the calipers up and disengages the brake.

In this system, the brake pedal has an inverse relationship with the amount of pressure in the brake lines. Pressing down on the pedal reduces the pressure in the air brake lines, which causes the calipers to tighten on the brake pads, and the brakes are applied.

Air Brake Drum Systems

In a lot of big trucks, you will notice that there are disc brakes on the front axles, but the axles on the trailer or even on the rear of the cabin have drum brake systems.

It is not uncommon for a single truck to have both disc and drum brakes. Both of these types of brakes are powered by air brake systems.

Drum brakes work slightly differently than disc brakes, as there is no caliper or rotor. Instead, there is a sealed ‘drum’ within which is the entire brake mechanism. When you open up the drum, there are 2 ‘leathers’ or ‘brake shoes,’ a number of springs, and near the top of the system is a piston.

When the brake is applied, the piston pulls on a brake shoe to extend it outward and press against the drum, which causes the vehicle to decelerate and eventually stop.

Similarly, if you pull the hand brake, there is another mechanism in the drum that pushes the brake pads out into the drum and then holds them there as long as the hand brake is applied.

In an air brake system, all of these changes are powered by the pressurized air stored in the air cylinder. In a regular vehicle, all of this is powered by the brake fluid that is pushed into the brakes when the brake is applied.

Air Brake Disc Systems

Disc brakes are a bit more straightforward in terms of mechanics—they are more reliable in performance, though they are more expensive in maintenance compared to drum brakes.

They are not the best option when you need brakes for trailers, but they do extremely well for the cabin.

https://commons.wikimedia.org/wiki/File:Air_disc_brake.jpg

Disc brakes are not enclosed like drum brakes. There is a rotor behind the wheel, which is mounted on the hub. Connected to the rotor are 2 calipers which are lined with a brake pad.

When the brake is applied, these calipers clamp down on the rotor, which causes the hub to decelerate, and the vehicle slows down. When the hand brake is applied, a piston closes the calipers, so they clamp down on the rotor and keep the wheel from spinning.

In an air brake system, the air brakes work in the inverse. The springs in the brake system are always fully loaded, so they are naturally clamped down on the calipers or the brake shoes.

When the air pressure in the air storage tanks is fully charged, it has enough pressure (usually around 65PSI) to lift the springs up. Pressing down on the pedal reduces pressure in the brake lines which makes the brakes come into contact with the rotor or the hub, which slows down the vehicle.

Emergency Air Brakes

These brakes are specially designed for the trailer that follows the vehicle and are useful if there is a problem with the regular braking system.

Usually, there is a knob on the dashboard or a lever in the cabin that can be used to deploy the emergency brakes. There is also a gauge or a digital meter that continuously shows the amount of air pressure in the brake lines.

If the pressure drops unusually quickly, or if there is no pressure at all, the emergency brake is used to help stop the trailer.

In nearly all trucks, there is a dedicated air cylinder for the trailer and a different one for the cabin. If the brakes on the trailer fail, the cabin remains unaffected, and vice versa.

The emergency brakes rely on the same springs that are used for the handbrake, so these are still usable regardless of whether there is pressure in the brake lines or not. The driver can manually slow down the cabin and bring the trailer to a controllable speed.

Advantages of Air Brakes

The biggest advantage of air brakes is the level of safety that they offer. All the features of the air brake system contribute to its safety.

One of the biggest issues with hydraulic systems is that if there is a leak in the system, the brakes are rendered useless. If the brake fluid level is low, the brakes won’t work properly.

With air brakes, the compressor can always draw in more air, compress it, and fill up the tank. Even if there is a minor leak in the system, the air brakes will continue to operate because the compressor is continuously feeding the system with more air.

High-pressure air is extremely dense and compact. Unlike fluid, there is no chance that the compressed air will deform or behave abnormally and cause a problem in the brake system.

When there is a lot of weight on the vehicle, the brake fluid is put under immense pressure to stop the vehicle—this is not an issue when you have air brakes.

They also don’t run the risk of getting air-locked like hydraulic systems, which also improves the reliability of this system and fewer instances to service brakes.

Flickr Image by David Stillman

Drawbacks of Air Brakes

The biggest drawback is that air brakes are not suitable for cold climates. In extremely low temperatures, the pressurized air will condense and create water bubbles in the system, which hinders the system’s performance.

This brake system requires a lot of space. Generally, there is no shortage of space on larger trucks, but it still takes room and adds weight to the vehicle.

These brakes require regular maintenance to keep them in good condition, and they need to be inspected more frequently than hydraulic systems to make sure everything is working as it should be.

Lastly, not every driver can drive an air brake vehicle. You need properly qualified drivers to operate these kinds of vehicles, and these drivers are paid more.

FAQ’s

Question 1: What are the advantages of air brakes over hydraulic brakes?

Answer: Air brakes have several advantages over hydraulic brakes, including:

- They are more fail-safe. If there is a leak in an air brake system, the brakes will still apply, albeit with less force. This is because the springs in the brake chambers will push the brake shoes against the drums or rotors.

- They are more effective at stopping heavy vehicles. Air brakes can provide more braking force than hydraulic brakes, which is important for large trucks and trailers.

- They are less prone to overheating. Air brakes use compressed air, which is a more efficient way to dissipate heat than hydraulic fluid.

Question 2: What are the different types of air brake systems?

Answer: There are two main types of air brake systems: single circuit and dual circuit.

- Single circuit systems: These systems use a single airline to operate all of the brakes on the vehicle. Single-circuit systems are less expensive to install and maintain, but they are also less safe. If there is a leak in the airline, the brakes will fail completely.

- Dual circuit systems: These systems use two airlines, one for the front brakes and one for the rear brakes. Dual circuit systems are more expensive to install and maintain, but they are also much safer. If there is a leak in one of the airlines, the brakes on the other axle will still work.

Question 3: What are the main components of an air brake system?

Answer: The main components of an air brake system are:

- Air compressor: This device compresses air and stores it in the air reservoirs.

- Air reservoirs: These tanks store the compressed air until it is needed for braking.

- Brake valves: These valves control the flow of air to the brake chambers.

- Brake chambers: These devices convert the compressed air pressure into mechanical force to apply the brakes.

- Brake shoes or pads: These parts apply friction to the drums or rotors to slow down the vehicle.

Question 4: How do air brakes work?

Answer: When the driver presses the brake pedal, it opens the brake valves. This allows the compressed air from the reservoirs to flow into the brake chambers. The pressure in the brake chambers pushes the brake shoes or brake pads against the drums or rotors, slowing down the vehicle.

Question 5: What are the signs that air brakes need to be repaired?

Answer: Some of the signs that air brakes need to be repaired include:

- Soft brake pedal: This means that the brake pedal is easy to press and does not provide much feedback.

- Spongy brake pedal: This means that the brake pedal feels squishy and does not return to its original position quickly.

- Noisy brakes: This can be a sign of worn pads or shoes or a problem with the brake calipers or rotors.

- Leaking air: If you hear a hissing sound coming from the air brake system, it is a sign of a leak.

- Poor braking performance: If the brakes are not stopping the vehicle effectively, it is a sign of a problem with the air brake system.

If you experience any of these problems, it is important to have your air brake system inspected and repaired by a qualified mechanic.

Conclusion of how do air brakes work

Air brakes are a very reliable form of the braking system if they are properly maintained and looked after.

They are extremely resilient and the best solution for high-load applications.

However, they need a competent person to operate them; otherwise, they can be hard to control, especially when the truck is loaded with a big payload.

1 thought on “How Do Air Brakes Work – Comprehensive Guide”

Comments are closed.