We’ll discuss the functions of primary and secondary filters in removing debris and purifying fuel, as well as provide step-by-step instructions on changing these vital components on larger engines. Additionally, we’ll cover proper procedures for replacing secondary filters near the engine block assembly without contaminating surfaces or compromising seals.

Do you need to change fuel filters on diesel vehicles? The answer is a resounding yes, and understanding why it’s crucial can help extend your engine’s life. In this comprehensive guide, we will delve into the importance of your diesel cars’ fuel filters and their role in maintaining clean fuel for optimal performance.

Beyond installation pre-filter only, do you need to change the fuel filter on diesel vehicles? Our expert advice includes bleeding air from the system after filter replacement to ensure efficient operation. Lastly, do you need to change the fuel filter on diesel vehicles frequently? We will explore recommended intervals for such changes and highlight the long-term benefits of maintaining clean fuel filters in your vehicle.

Jump To

- 1 The Importance of Diesel Fuel Filters

- 2 Primary Filter’s Role in Removing Large Debris

- 3 Secondary Filter for Finer Particle Removal

- 4 Do You Need to Change the Fuel Filter on Your Diesel Vehicle?

- 5 Bleeding Air from Your Vehicle’s Fuel System After Filter Replacement

- 6 Do You Need to Change the Fuel Filter on Diesel?

- 7 Double-checking Work Performed During Filter Changes

- 8 The Benefits of Regular Diesel Fuel Filter Maintenance

- 9 FAQ‘s

- 10 Conclusion – Do You Need to Change Fuel Filters on Diesel Vehicles

The Importance of Diesel Fuel Filters

Diesel engines rely on two fuel filters, a primary and secondary filter, to maintain performance and prevent engine failures. These filters work together to remove debris and contaminants from the fuel before it reaches the diesel injector fuel pump itself, thus poor fuel efficiency prolonging its lifespan and ensuring optimal vehicle performance.

Primary Filter’s Role in Removing Large Debris

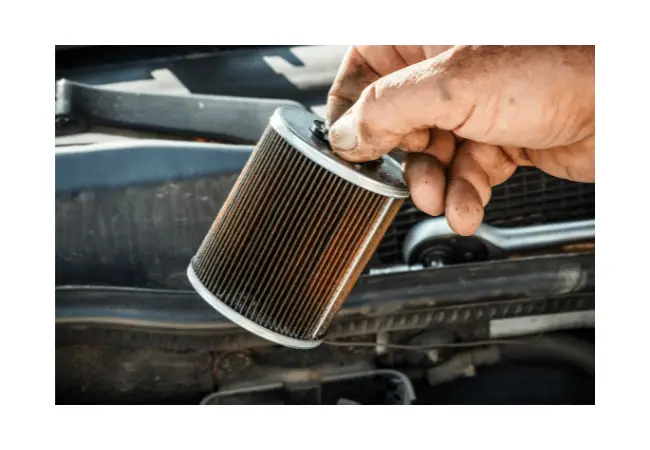

The primary diesel fuel filter is responsible for removing larger particles from the car and fuel supply. It typically sits between the vehicle’s fuel storage tank and fuel pump, capturing contaminants and impurities such as rust or dirt that may have entered during refueling or during storage tank bottom. By filtering out these impurities, this component helps protect your vehicle’s delicate internal components like injectors from damage caused by abrasive materials.

Secondary Filter for Finer Particle Removal

In addition to the primary diesel fuel filter, diesel vehicles also generally utilize a secondary fuel filter designed specifically for finer particle removal. Located closer to the car and engine block assembly than its counterpart, this component captures smaller debris not caught by the first stage filtration process. This ensures that only clean fuel reaches your vehicle’s fuel injectors, preventing clogs or other issues related to poor combustion or poor fuel efficiency.

- Maintaining Clean Fuel: Regularly changing both primary and secondary diesel filters is crucial in maintaining a consistent flow of clean fuel throughout your engine system.

- Prolonged Engine Life: Properly functioning fuel filters help to prolong the life of your vehicle’s engine by preventing contaminants from entering and causing damage.

- Improved Performance: Clean fuel ensures optimal combustion, resulting in better overall performance and efficiency for your diesel vehicle.

In conclusion, it is essential to regularly inspect and replace both primary and secondary diesel fuel filters as part of routine maintenance for diesel trucks. Regularly changing the fuel filters on diesel trucks can not only protect your vehicle’s manual engine from harm but also increase its performance over time.

It is essential to understand the importance of diesel fuel filters and their role in maintaining engine performance. With that being said, it is important to know how to properly change primary fuel filters on larger engines for optimal efficiency.

Key Takeaway:

Diesel engines require both primary and secondary fuel filters to remove debris and contaminants from the fuel supply. The primary filter captures larger particles while the secondary diesel fuel filter removes finer particles, ensuring clean fuel reaches the injectors for optimal performance. Regularly changing these filters is crucial in maintaining engine life and improving overall efficiency.

Do You Need to Change the Fuel Filter on Your Diesel Vehicle?

As a vehicle maintenance professional, you know that regular maintenance is essential to keep your diesel vehicle running smoothly. One important component that requires attention is the fuel filter. The fuel filter helps remove debris and contaminants from the diesel fuel, ensuring that clean fuel reaches your engine and maintains optimal performance. But how do you know when it’s time to change your diesel fuel filter?

Experts recommend a fuel filter change every 10,000 to 15,000 miles or at least once a year. However, if you notice any of the following signs, it may be time to change your fuel filter sooner:

- Your engine is running rough or stalling

- You’re experiencing a loss of power or acceleration

- Your fuel efficiency has decreased

- You notice a strong odor of diesel fuel

If you’re experiencing any of these symptoms, it’s important to have your fuel filter checked and replaced if necessary. A clogged fuel filter can cause damage to your fuel injectors and fuel line, leading to costly repairs.

Changing Your Fuel Filter

If you do need to change the fuel filter on diesel vehicles and you’re comfortable performing maintenance tasks on your diesel vehicle, changing the fuel filter on diesel cars can be a relatively simple task. Here are the basic steps:

- Turn off the engine: Always make sure your vehicle’s engine is turned off before attempting any maintenance tasks.

- Locate the fuel filter: The fuel filter is typically located in the engine compartment or along the fuel line under the vehicle.

- Relieve fuel pressure: Before removing the fuel filter, relieve the fuel pressure by removing the fuel pump fuse or relay and starting the engine until it stalls.

- Remove old filter: Use a wrench or pliers to carefully loosen and remove the old fuel filter from its housing.

- Install new filter: Insert the new fuel filter into the housing, making sure it’s properly seated and secured.

- Start the engine: Once the new fuel filter is installed, start the engine and check for leaks.

It’s important to follow the manufacturer’s instructions for your specific diesel vehicle when changing the fuel filter. If you’re unsure about any aspect of the pre filter up process or need assistance, consult a professional mechanic to ensure optimal results.

Regularly changing your fuel filter is an important part of diesel vehicle maintenance. By keeping your fuel filter clean and functioning properly, you can help ensure that your diesel engine still runs smoothly and efficiently for years to come.

Prior to making an effort to switch out the main fuel filter on bigger motors, it is essential to be aware of all safety precautions that must be observed. With these steps in mind, replacing secondary fuel filters near engine block assemblies can become a straightforward task with proper preparation and knowledge.

Replacing Secondary Fuel Filters Near Engine Block Assembly

When it comes to maintaining the performance and longevity of enough fuel out of your diesel vehicle’s fuel tank, replacing secondary fuel filters mounted near the engine block assembly is a crucial step. These filters play an essential role in removing finer particles from the diesel fuel, ensuring that clean fuel reaches your diesel engine’s fuel injectors.

Tips for Properly Installing New Secondary Filters

- Preparation: Before starting, make sure you have all the necessary tools and replacement parts on hand. This includes a new filter, an O-ring gasket (if applicable), and any specific wrenches or sockets required.

- Cleanliness: Ensure that the area around the filter housing is free from dirt or grime buildup before attempting to remove it. Wipe the area around the filter with a cloth or brush to clear away any dirt.

- R&R Procedure: Carefully unscrew or unclamp the old filter from its housing, taking care not to damage surrounding components. Replace with a new filter according to manufacturer specifications.

- O-Ring Inspection: Check for damaged O-rings on both old and new filters; replace as needed.

Ensuring Leak-Free Connections After Replacement

To prevent leaks when restarting your vehicle after completing maintenance tasks like changing or servicing these crucial components, follow these steps:

- Tighten T-handles securely, ensuring a snug fit between the filter and its housing.

- Inspect all connections for proper seating and alignment. Adjust as necessary to prevent leaks or fuel line restrictions.

- Start your vehicle’s engine and allow it to idle for several minutes while checking for any signs of leakage around the newly installed filter. If you notice any drips or seepage, shut off the engine immediately and recheck your work before attempting to drive.

Incorporating these tips into your regular diesel vehicle maintenance routine will help ensure that your secondary fuel filters are always functioning optimally, providing a free flow of clean fuel to your engine and protecting it from potential damage caused by contaminants in the diesel supply.

Replacing secondary fuel filters near the engine block assembly is an important part of maintaining a healthy vehicle, and it’s essential to install them to ensure that all connections are secure. Now let’s look at the next step in replacing your diesel filter: bleeding air from the system after replacement.

Key Takeaway:

To maintain the performance and longevity of your diesel vehicle, it is crucial to replace secondary fuel filters near the engine block assembly. Proper installation includes ensuring cleanliness, inspecting O-rings, and checking for leak-free connections after replacement. Incorporating these tips into regular maintenance routines will ensure optimal function and protection against potential damage caused by contaminants in the diesel supply.

Bleeding Air from Your Vehicle’s Fuel System After Filter Replacement

After replacing both primary and secondary diesel fuel filters, it is crucial to bleed trapped air bubbles within your vehicle’s fuel system. This critical step prevents premature wear issues and ensures smooth operation post-maintenance. In this section, we will discuss how to locate bleeder valves or screws specific to your model and properly bleed free flow of the air from the vehicle’s manual system.

Identifying Bleeder Valves or Screws on Various Models

Different diesel vehicles have varying locations for their bleeder valves or screws. Typically, you can find them near the fuel injectors, on top of the fuel filter housing, or along the fuel line leading to the engine. Consult your owner’s manual for exact specifications regarding your specific make and model.

Properly Bleeding Air From The System

- Turn off: Before starting any work on bleeding air from your vehicle’s fuel system after a filter change, ensure that you turn off its engine first.

- Safety gear: Wear gloves and safety glasses as a precautionary measure when working with diesel fuels.

- Bleed valve/screw location: Locate the appropriate bleeder valve(s) or screw(s) according to your vehicle’s manual instructions.

- Fuel catch container: Place a suitable receptacle beneath each valve/screw before opening it; this helps capture any escaping liquid during this process.

- Air removal: Open each identified valve/screw, allowing gases to escape until only liquid remains visible. You may need to pump the fuel primer (if equipped) or crank the engine briefly for this step.

- Closing valves/screws: Once all air has been bled from your vehicle’s fuel system, close each valve/screw securely.

By following these steps and properly bleeding trapped air within your diesel vehicle’s fuel system after replacing both primary and secondary filters, you can ensure fuel tank and optimal performance and prevent potential issues related to premature wear on components such as fuel pumps and injectors or pumps.

It is important to bleed fuel to drain the air from your vehicle’s fuel system after replacing a filter in order to ensure that it functions properly. Additionally, double-checking work performed during filter changes can help you identify any potential issues and prevent future problems with your car maintenance components.

Key Takeaway:

After replacing both primary and secondary diesel fuel filters, it is crucial to bleed trapped air bubbles within your vehicle’s fuel system. This critical step prevents premature wear issues and ensures smooth operation post-maintenance. To do this, locate the appropriate bleeder valve(s) or screw(s), open them to remove air, and close them securely once all air has been bled from the system.

Do You Need to Change the Fuel Filter on Diesel?

The answer is yes. The fuel filter is an essential component of your vehicle’s fuel system, and it needs to be changed regularly to ensure optimal performance.

Double-checking Work Performed During Filter Changes

It is important to always double-check work performed during diesel fuel filter changes by examining housings closely for damaged O-ring gaskets that may need replacement. Ensuring oil-absorbent sheets or pads placed beneath areas worked upon were effective at capturing spills and drips is crucial for maintaining a clean work environment.

Inspecting Filter Housings for Damage

After completing the diesel fuel filter change, take some time to inspect the filter housing, especially the O-rings. A damaged or worn-out O-ring can cause leaks and affect your vehicle’s performance. Look out for any signs of wear, cracks, or swelling on the rubber seal. If you find any issues with the O-ring gasket, replace it immediately to prevent potential problems down the road.

Importance of Using Absorbent Materials During Maintenance

- Maintaining cleanliness: Fuel spills are not only messy but also hazardous. By using absorbent materials like oil-absorbent sheets or pads during maintenance tasks such as changing diesel fuel filters, you can keep your workspace clean and safe from potential accidents caused by slippery surfaces.

- Eco-friendly disposal: After capturing spills and drips with absorbents, dispose of them properly according to local regulations regarding hazardous waste disposal. Keeping the workspace tidy helps to ensure that hazardous substances do not get into areas where they can cause damage to wildlife and their habitats.

- Better visibility: Clean working environments make it easier to spot any loose connections or other issues related to the fuel line and filter replacement. Maintaining a neat workspace can help to quickly identify any issues that may arise during the maintenance process.

In summary, always double-check your work when changing diesel fuel filters to ensure optimal vehicle performance and a clean working environment. Inspect filter housings for damage, replace O-ring gaskets as needed, and use absorbent materials to capture spills and drips throughout the process.

It is important to double-check work performed during diesel filter changes, as this can help ensure that any potential issues are caught and resolved quickly. By regularly maintaining diesel fuel filters, it is possible to improve the performance of a vehicle’s fuel tank while also protecting its engine from contaminants.

Key Takeaway:

If you own a diesel vehicle, it is important to change the fuel filter regularly. After changing the fuel filter change part, double-check for any damage and use absorbent materials to maintain cleanliness and prevent potential hazards. By doing so, you can ensure the optimal performance of your vehicle and identify any issues that may arise during maintenance.

The Benefits of Regular Diesel Fuel Filter Maintenance

Changing diesel fuel filters regularly is essential to improving your vehicle’s performance and longevity. By inspecting and replacing both primary and secondary filters as needed, you can protect your engine from damage due to contaminants in the fuel supply while also following proper safety precautions during the process.

Improving Vehicle Performance Through Regular Filter Changes

Maintaining clean fuel by changing diesel fuel filters at regular intervals helps ensure that your engine runs smoothly and efficiently. A clogged diesel fuel filter can lead to poor acceleration, reduced power output, increased emissions, and even potential engine failure. A well-kept filtration system can bring out the best in your diesel vehicle, with improved acceleration and more power.

- Better acceleration response

- Increase in power output

- Reduced harmful emissions

- Prolonged engine life expectancy

Diesel engines are particularly sensitive to contamination within their complex injection systems. As such, it’s crucial for diesel vehicle owners to replace their primary and secondary fuel filters periodically according to manufacturer recommendations or when signs of a clogged or clogged fuel filter become apparent.

Diesel fuel contamination issues, such as water intrusion or debris buildup within the system, may result in costly repairs if left unaddressed:

- Fuel injectors becoming damaged or blocked

- Decreased fuel efficiency

- Increased wear on the diesel injector pump

- Potential engine failure

In conclusion, regular maintenance of your vehicle’s diesel fuel filters is a small investment that can pay off in terms of improved performance and protection against costly repairs. By staying proactive with diesel fuel filter part changes, you’ll keep your engine running smoothly while extending its overall lifespan.

FAQ‘s

Do You Need to Change the Fuel Filter on Diesel?

Yes, changing the fuel filter on a diesel engine is essential for maintaining optimal performance and preventing potential damage. Diesel fuel filters remove contaminants from the fuel, ensuring that clean fuel reaches the engine. Regularly replacing these filters helps maintain efficiency and prolongs your vehicle’s lifespan.

What Happens If You Don’t Change Fuel Filter on Diesel Truck?

If you don’t change the fuel filter in a diesel truck, it can become clogged with debris and contaminants. This may lead to reduced engine performance, poor mileage, difficulty starting or stalling issues, increased emissions levels, and potentially costly repairs due to damaged components such as injectors or fuel pumps.

Do You Really Need to Change Fuel Filter?

Absolutely. Changing your vehicle’s fuel filter, whether it’s gasoline or diesel-powered, is crucial for maintaining proper engine function. A clean fuel filter ensures that only uncontaminated fuel reaches your motor while also protecting sensitive parts like injectors from premature wear caused by particles present in fuels.

What Damage Can Be Caused by Not Replacing Fuel Filters in a Diesel-Fuel System?

- Clogged injectors lead to decreased power output

- Fuel pump failure due to excessive strain

- Poor combustion results in higher emissions levels

- Inefficient operation causing lower miles per gallon (MPG)

- Potential catastrophic engine failure requiring expensive repairs

Conclusion – Do You Need to Change Fuel Filters on Diesel Vehicles

In conclusion, maintaining clean diesel fuel filters is crucial for the proper functioning of your engine. The primary filter removes larger debris while the secondary filter purifies the fuel. When changing these filters, it’s important to follow safety precautions and properly bleed air from the system. Regularly changing your diesel fuel filters can have long-term benefits for your vehicle.

So, do you need to change the fuel filter on a diesel? Yes! Make sure to keep your service up with recommended service intervals and double-check your work after each replacement.

1 thought on “Do You Need to Change Fuel Filters on Diesel Vehicles – 4 Tips for Replacing”

Comments are closed.