Maintaining your vehicle is essential to ensure its longevity and peak performance. One crucial aspect of car maintenance is understanding the role of various components under the hood. One such component that often goes unnoticed but plays a vital role in preserving your engine’s health is the oil filter. In this article, we’ll delve into the world of engine care and explore the question: What does an oil filter do?

To truly appreciate the significance of an oil filter, we must first grasp the primary function it serves in an automobile’s engine system. The oil filter is a relatively small yet incredibly important device designed to trap and remove contaminants from the engine’s lubricating oil. As the engine runs, it generates heat and friction, leading to the production of tiny metal particles, dirt, and sludge. Without an oil filter, these harmful impurities would circulate freely through the engine, causing excessive wear and tear. In the next paragraph, we’ll dive deeper into how the oil filter accomplishes this critical task and why it is indispensable for your vehicle’s well-being.

In essence, an oil filter acts as the guardian of your engine’s health, ensuring that the oil circulating through the system remains clean and free from damaging particles. It achieves this by employing a fine mesh or cellulose filter medium that captures contaminants as the oil passes through it. Over time, as these contaminants accumulate, the filter becomes less effective, which is why regular oil and filter changes are essential. Neglecting this maintenance can lead to decreased engine performance, reduced fuel efficiency, and potentially costly repairs. So, the next time you wonder about the importance of an oil filter, remember that it plays a pivotal role in safeguarding your engine and ensuring your vehicle continues to run smoothly.

Clean oil is essential for optimal engine performance and longevity. When oil is clean, it effectively lubricates moving parts, reducing friction and wear, and leading to improved fuel efficiency and overall performance. Contaminated oil, on the other hand, loses its ability to perform these vital functions, resulting in increased friction, heat, and engine wear. Over time, dirty oil can cause sludge buildup and accelerate the degradation of engine components, potentially leading to costly repairs or even engine failure. Regular oil changes and using the right type of oil for your vehicle can help maintain clean oil, ensuring optimal engine performance and prolonging its life.

The oil filter is a critical component in an internal combustion engine’s lubrication system. Its primary purpose is to remove impurities, such as dirt, debris, and metal particles, from the engine oil before it circulates through the engine. By doing so, the oil filter ensures that the oil remains clean and can effectively perform its lubrication, heat dissipation, sealing, and cleaning functions. A well-maintained oil filter contributes to improved engine performance, fuel efficiency, and overall engine longevity, making it an essential component of regular vehicle maintenance.

Jump To

- 1 Understanding the Oil Filter

- 2 Types of oil filters

- 3 The Role of the Oil Filter in Engine Performance

- 4 Protection of engine components

- 5 The Importance of Regular Oil Filter Maintenance

- 6 Recommended oil filter change intervals

- 7 Signs that your oil filter needs changing

- 8 Choosing the Right Oil Filter for Your Vehicle

- 9 Popular oil filter brands and their features

Understanding the Oil Filter

An oil filter is composed of several key components that work together to efficiently remove contaminants from the engine oil. The filter medium, usually made from synthetic or cellulose fibers, is the primary component responsible for trapping impurities as oil flows through it. A bypass valve ensures that oil continues to circulate through the engine even if the filter becomes clogged, preventing oil starvation and engine damage.

The anti-drain back valve prevents oil from draining out of the filter when the engine is turned off, ensuring that oil is readily available for lubrication upon startup. Lastly, the end caps and base plate provide structural support to the filter medium and facilitate proper sealing and connection to the engine’s lubrication system.

Filter medium

- The filter medium is the core component of an oil filter, responsible for physically trapping and removing contaminants from the engine oil. It is typically constructed from cellulose, synthetic fibers, or a blend of both materials. Cellulose, derived from plant fibers, is an economical option that offers adequate filtration for most standard applications. Synthetic fibers, on the other hand, provide superior filtration efficiency, longer service life, and higher resistance to extreme temperatures. Some filters also incorporate a wire mesh support structure to reinforce the filter medium and prevent it from collapsing under pressure. The filter medium’s design, pore size, and surface area determine its overall effectiveness in capturing contaminants and ensuring clean oil circulation throughout the engine.

Bypass valve

- The bypass valve is an essential safety feature of an oil filter, designed to ensure continuous oil flow in the event of a clogged filter or extremely cold temperatures that may cause the oil to thicken. When the pressure differential across the filter medium exceeds a predetermined threshold, the bypass valve opens, allowing oil to bypass the filter and circulate directly through the engine. Although this oil is unfiltered, it is still preferable to oil starvation, which can cause severe engine damage. The bypass valve helps protect the engine during adverse conditions while serving as a reminder that the oil filter needs to be replaced promptly.

Anti-drain back valve

- The anti-drain back valve is a crucial component in many oil filters, preventing oil from draining out of the filter when the engine is not running. This valve ensures that oil remains within the filter, making it readily available for lubrication as soon as the engine starts. Without an anti-drain back valve, the engine could experience a brief period of oil starvation during startup, resulting in increased wear on engine components. The anti-drain back valve is typically constructed from rubber or silicone and is located at the base of the filter, allowing oil to flow into the filter but preventing it from flowing back out.

End caps and base plate

- The end caps and base plate are structural components of the oil filter, providing support and ensuring proper sealing and connection to the engine’s lubrication system. The end caps, typically made of metal or thermoplastic material, hold the filter medium in place and prevent unfiltered oil from bypassing the medium. The base plate, also made of metal, features an inlet and outlet port for oil to enter and exit the filter. Additionally, it houses the gasket, which forms a tight seal between the filter and the engine to prevent oil leaks. The base plate is designed with a threaded center hole, enabling the filter to be securely attached to the engine block. Together, these components ensure the filter’s integrity and effectiveness in maintaining clean oil circulation throughout the engine.

Types of oil filters

There are several types of oil filters designed to meet the varying needs of different engines and operating conditions. Mechanical filters use a pleated paper or synthetic element to trap contaminants as oil flows through the filter. Cartridge and spin-on filters are self-contained units that house the filter medium and can be easily replaced during routine maintenance. Magnetic filters use a magnetic element to attract and capture metal particles suspended in the oil. Sedimentation filters rely on gravity to separate heavier contaminants from the oil, allowing them to settle at the bottom of the filter housing. Centrifugal filters use a spinning rotor to create a centrifugal force that separates contaminants from the oil, depositing them on the filter’s outer wall.

Each type of filter has its own advantages and limitations, making it essential to choose the right filter for your specific vehicle and driving conditions.

Mechanical

- Mechanical oil filters are the most common type of oil filter, typically featuring a paper or synthetic filter media that captures contaminants as the oil flows through the filter element. Mechanical filters can be further divided into two categories: full-flow and bypass filters. Full-flow filters capture all of the oil that flows through the engine, while bypass filters divert a small portion of the oil flow to be filtered separately. Mechanical filters are durable and effective, making them a popular choice for most applications.

Cartridge and spin-on

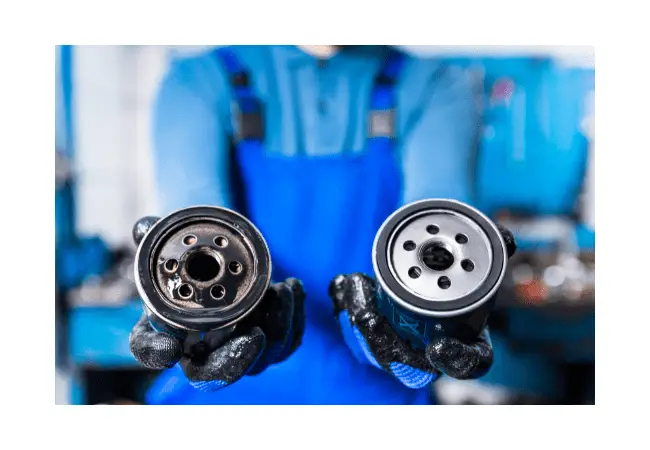

- Cartridge and spin-on oil filters are two common types of mechanical oil filters. Cartridge filters feature a replaceable filter element that is installed within a permanent housing. Spin-on filters are self-contained, disposable filters that thread onto a filter mount located on the engine block or oil cooler. Both types of filters can provide effective filtration and are easy to replace during routine maintenance.

Magnetic

- Magnetic oil filters utilize a magnet or series of magnets to attract and capture ferrous contaminants in the oil. These filters are typically used in conjunction with traditional mechanical filters and can provide additional filtration capability for removing metal particles from the oil.

Sedimentation

- Sedimentation oil filters are designed to capture large particles and debris through a process of gravity separation. As oil flows through the filter, it passes through a series of plates or screens that trap contaminants in the oil. Sedimentation filters are typically used in heavy-duty applications where large debris is a concern.

Centrifugal

- Centrifugal oil filters utilize centrifugal force to separate contaminants from the oil. As oil flows through the filter, it passes through a series of vanes or fins that spin the oil, creating a centrifugal force that causes contaminants to be thrown to the outer edge of the filter. Centrifugal filters can be effective at removing larger particles and debris from the oil and are commonly used in high-performance or racing applications.

By understanding the different types of oil filters available and their respective strengths and weaknesses, vehicle owners can make informed decisions when selecting the right filter for their engine and driving needs.

The Role of the Oil Filter in Engine Performance

An oil filter plays a vital role in removing contaminants and impurities from engine oil, ensuring that it remains clean and effective in performing its essential functions. As oil circulates through the engine, it picks up various contaminants such as dirt, debris, and metal particles produced by engine wear. If left unfiltered, these impurities can cause abrasive wear, accelerate component degradation, and hinder engine performance. The oil filter’s primary function is to capture and remove these contaminants, preventing them from circulating throughout the engine and causing damage. By doing so, the oil filter helps maintain optimal engine performance, fuel efficiency, and overall engine longevity.

Dirt and debris

- Dirt and debris are common contaminants found in engine oil, originating from various sources such as the environment, engine wear, and manufacturing processes. These contaminants can be abrasive, causing increased friction and wear on engine components as they circulate with the oil. The oil filter is designed to trap and remove dirt and debris from the oil, preventing them from causing damage to the engine. By effectively filtering out these contaminants, the oil filter ensures that clean oil can properly lubricate and protect the engine’s internal components, promoting optimal performance and longevity.

Metal particles

- Metal particles are another type of contaminant found in engine oil, typically resulting from the normal wear and tear of engine components. As metal parts grind against each other during engine operation, tiny metal particles can break off and become suspended in the oil. If not removed, these particles can cause abrasive wear, further damaging engine components and leading to potential engine failure. The oil filter plays a crucial role in capturing and removing metal particles from the oil, preventing them from causing additional wear and damage. By filtering out metal particles, the oil filter helps maintain engine performance, fuel efficiency, and overall engine longevity.

Sludge and varnish

- Sludge and varnish are byproducts of engine oil breakdown that can accumulate over time, negatively impacting engine performance and causing damage to internal components. Sludge is a thick, gel-like substance formed from a combination of oxidized oil, dirt, and other contaminants. Varnish, on the other hand, is a hard, glossy substance that forms on engine surfaces due to the chemical breakdown of oil additives. Both sludge and varnish can restrict oil flow, impair heat transfer, and increase engine wear. The oil filter plays a vital role in capturing and removing sludge and varnish, ensuring that clean oil can effectively lubricate and protect engine components. Regular oil and filter changes can help prevent the buildup of sludge and varnish, contributing to optimal engine performance and longevity.

Protection of engine components

The oil filter is crucial in protecting engine components from premature wear and potential damage. By removing contaminants and impurities from the engine oil, the filter ensures that the oil remains clean and is able to effectively lubricate and protect critical engine parts. Clean oil reduces friction between moving parts such as bearing surfaces, piston rings, and cylinder walls, minimizing wear and prolonging component life. Additionally, clean oil aids in heat dissipation, helping to prevent overheating and maintain proper operating temperatures for engine components. By providing a constant supply of clean oil, the oil filter significantly contributes to the protection and longevity of an engine’s vital components, promoting optimal performance and reducing maintenance costs over time.

Bearing surfaces

- Bearing surfaces in an engine are critical contact points between moving parts, such as the crankshaft and connecting rod bearings, where friction and wear are most likely to occur. Proper lubrication with clean oil is essential to minimize friction and protect these surfaces from damage. The oil filter plays a crucial role in ensuring that the oil remains free of contaminants, which can cause abrasive wear on bearing surfaces, leading to premature component failure. By effectively filtering out impurities, the oil filter helps maintain the integrity of bearing surfaces, promoting optimal engine performance, fuel efficiency, and overall engine longevity.

Piston rings and cylinder walls

- Piston rings and cylinder walls are vital to engine components that require proper lubrication and protection to function efficiently and reliably. Piston rings help to create a seal between the piston and cylinder wall, preventing combustion gases from escaping into the crankcase and maintaining efficient engine operation. Cylinder walls are subject to constant contact with piston rings, which can cause wear and tear if not adequately lubricated. The oil filter ensures that clean oil is available to lubricate these components, preventing excessive friction and wear. By filtering out contaminants that can cause abrasive damage, the oil filter contributes to the longevity and optimal performance of piston rings and cylinder walls.

Valvetrain components

- The valvetrain is an essential part of an internal combustion engine, responsible for regulating the intake and exhaust of air and fuel into and out of the combustion chamber. Valvetrain components, such as camshafts, lifters, and rocker arms, require clean oil for proper lubrication and protection against wear. Contaminants in the oil can cause increased friction, wear, and damage to these components, which can result in reduced engine performance, increased emissions, and potential engine failure. The oil filter plays a vital role in maintaining clean oil for the lubrication and protection of valvetrain components, ensuring their efficient operation and promoting overall engine performance and longevity.

The Importance of Regular Oil Filter Maintenance

A clogged or faulty oil filter can have detrimental effects on an engine’s performance and longevity. When an oil filter becomes clogged, it can impede the flow of oil through the engine, leading to inadequate lubrication of critical components. This can result in increased friction, wear, and heat generation, ultimately causing accelerated component degradation and potential engine failure. Additionally, a faulty oil filter may not effectively remove contaminants from the oil, allowing them to circulate throughout the engine and cause abrasive wear. In some cases, a malfunctioning bypass valve within the filter may allow unfiltered oil to circulate, further exacerbating the issue.

Decreased engine performance

- A well-maintained oil filter is essential for optimal engine performance, as it ensures that clean oil is available to lubricate and protect the engine’s internal components. When an oil filter becomes clogged or faulty, it can lead to decreased engine performance. Inadequate lubrication due to a compromised oil filter can result in increased friction, heat generation, and wear on engine components, which can negatively impact fuel efficiency, power output, and overall engine responsiveness. To maintain peak engine performance, it is crucial to change the oil filter at recommended intervals and address any potential issues promptly.

Increased wear and tear

- A clogged or faulty oil filter can lead to increased wear and tear on an engine’s internal components. When the oil filter fails to effectively remove contaminants from the oil, these impurities can circulate throughout the engine, causing abrasive wear on critical parts such as bearing surfaces, piston rings, and cylinder walls. This increased wear and tear can shorten the lifespan of engine components, resulting in higher maintenance costs and a greater likelihood of component failure. Regular oil filter changes can help to minimize wear and tear and promote engine longevity.

Potential engine damage

- Failure to address a clogged or faulty oil filter can ultimately lead to significant engine damage. When contaminants are allowed to circulate through the engine, they can cause abrasive wear, which can lead to premature component failure. Furthermore, a clogged oil filter can impede the flow of oil through the engine, resulting in inadequate lubrication and increased heat generation. This lack of proper lubrication and cooling can cause components to overheat, warp, or seize, potentially leading to catastrophic engine failure. To protect your engine and maintain its reliability, it is essential to change the oil filter at the recommended intervals and address any potential issues as soon as they arise.

Recommended oil filter change intervals

Oil filter change intervals can vary depending on the type of filter, the type of oil used, driving conditions, and the specific vehicle make and model. As a general rule, it is recommended to change your oil filter with every oil change to ensure optimal engine performance and protection. For conventional oil, this is typically every 3,000 miles or three months, whichever comes first. For synthetic oil, the intervals may be extended to between 5,000 and 10,000 miles or every six months. Always consult your vehicle owner’s manual for the manufacturer’s recommended oil and filter change intervals, as they may vary based on your specific vehicle and driving conditions.

Manufacturer guidelines

- When it comes to maintaining your vehicle and ensuring optimal engine performance, it is essential to follow the manufacturer’s guidelines for oil filter changes and maintenance. Vehicle manufacturers provide specific recommendations for oil and filter change intervals based on extensive testing and analysis, taking into account factors such as engine design, driving conditions, and the type of oil used. These guidelines can be found in your vehicle owner’s manual, which serves as a valuable resource for understanding the specific maintenance requirements for your vehicle. Adhering to the manufacturer’s guidelines can help you prevent engine damage, extend the life of your engine, and maintain optimal performance.

Factors affecting oil filter life

- Several factors can affect the life of an oil filter, making it essential to monitor your vehicle’s condition and address potential issues as they arise. Some of the factors that can impact oil filter life include:

a. Driving conditions: Frequent short trips, stop-and-go traffic, and driving in dusty or dirty environments can lead to increased contamination of the engine oil, putting additional strain on the oil filter and potentially shortening its lifespan.

b. Engine wear: As an engine ages, the normal wear and tear of internal components can result in an increased amount of metal particles and debris in the oil, requiring the oil filter to work harder to remove these contaminants.

c. Type of oil: The type of oil used in your vehicle can also affect oil filter life. Synthetic oils typically offer superior protection and extended service intervals compared to conventional oils, potentially allowing for longer oil filter life.

d. Quality of the oil filter: Not all oil filters are created equal. High-quality filters typically feature better filtration materials and construction, which can extend the filter’s lifespan and overall effectiveness.

By being aware of these factors and monitoring your vehicle’s condition, you can make informed decisions about when to change your oil filter, ensuring that your engine remains well-lubricated and protected.

Signs that your oil filter needs changing

There are several signs that your oil filter may need changing, some of which include:

- Decreased engine performance: A clogged oil filter can lead to inadequate lubrication of engine components, resulting in reduced performance and potential engine damage.

- Increased oil consumption: A faulty oil filter may cause the engine to consume oil at a higher rate than normal, indicating that the filter is not effectively removing contaminants.

- Dirty or dark oil: If the oil appears excessively dark or dirty, it may be a sign that the oil filter is not effectively filtering out impurities.

- Check engine or oil pressure warning lights: If your vehicle’s check engine or oil pressure warning lights illuminate, it could indicate an issue with the oil filter or oil pressure, necessitating a filter change.

Unusual engine noise: If you notice increased engine noise, such as knocking or ticking, it could be a sign that the oil filter is not effectively providing proper lubrication to engine components.

- To ensure optimal engine performance and longevity, it is essential to change your oil filter at the recommended intervals and address any potential issues promptly.

Poor performance or reduced fuel efficiency

- Poor performance or reduced fuel efficiency can be indicative of a clogged or faulty oil filter. When an oil filter becomes clogged, it can impede the flow of oil through the engine, leading to inadequate lubrication of critical components. This can result in increased friction and heat generation, which can negatively impact engine performance, power output, and fuel efficiency. Moreover, a compromised oil filter may not effectively remove contaminants from the oil, allowing them to circulate throughout the engine and cause further performance issues. To address these problems and maintain optimal engine performance, it is essential to change the oil filter at the recommended intervals and address any potential issues promptly.

Engine noises or knocking sounds

- Engine noises or knocking sounds can be a sign of an oil filter issue, as they may indicate inadequate lubrication of internal engine components. A clogged or faulty oil filter can restrict the flow of oil, preventing proper lubrication of critical engine parts such as bearing surfaces, piston rings, and valvetrain components. Insufficient lubrication can lead to increased friction and wear, causing unusual noises such as knocking or ticking sounds. If you notice such noises, it’s essential to inspect the oil filter and related components and address any issues to prevent further damage to the engine.

Oil pressure warning light

- The oil pressure warning light is designed to alert the driver when the engine’s oil pressure falls below a predetermined level, which can be indicative of a clogged or faulty oil filter. When an oil filter becomes clogged, it can impede the flow of oil through the engine, resulting in decreased oil pressure. Additionally, a malfunctioning bypass valve within the filter may cause unfiltered oil to circulate or even restrict oil flow, exacerbating the issue. If the oil pressure warning light illuminates, it is crucial to address the problem as soon as possible, as continuing to drive with low oil pressure can lead to severe engine damage. In such cases, it is essential to check the oil filter and related components and change the filter as necessary to restore proper oil pressure and protect the engine.

Choosing the Right Oil Filter for Your Vehicle

When selecting an oil filter for your vehicle, there are several factors to consider to ensure optimal engine performance and protection. Some of these factors include:

- Compatibility: Ensure that the oil filter is compatible with your specific vehicle’s make and model. Refer to your vehicle owner’s manual or consult an automotive professional to determine the correct filter for your engine.

- Filter media: The filter media is the primary component responsible for capturing contaminants in the oil. Consider filters with high-quality, synthetic media that provide superior filtration efficiency and capacity.

- Construction: The overall construction and design of the oil filter can impact its durability and effectiveness. Look for filters with features such as strong end caps, a sturdy base plate, and a reliable anti-drain back valve to ensure consistent performance and prevent oil leakage.

- Bypass valve: A quality bypass valve is essential to ensure that oil continues to flow through the engine in the event that the filter becomes clogged. Choose a filter with a well-designed bypass valve that maintains adequate oil flow without compromising filtration performance.

- Brand reputation: Consider the reputation of the oil filter brand, as well-known brands often have a history of providing reliable and high-quality products.

By carefully considering these factors, you can select an oil filter that provides optimal engine protection and performance for your vehicle.

Compatibility with your vehicle

- When choosing an oil filter, it is crucial to ensure that the filter is compatible with your specific vehicle’s make and model. Using an incompatible oil filter can lead to inadequate filtration, oil leaks, or even engine damage. To determine the correct oil filter for your vehicle, consult your owner’s manual or use an online oil filter reference guide. In some cases, you may need to consult with an automotive professional to ensure that you are selecting the appropriate filter for your engine’s needs.

Filtration efficiency

- Filtration efficiency refers to the ability of an oil filter to effectively capture and remove contaminants from the engine oil. A higher filtration efficiency means that a greater percentage of particles are removed from the oil, leading to cleaner oil and better engine protection. When choosing an oil filter, look for filters with high-quality filter media, such as synthetic or cellulose materials, which can provide superior filtration efficiency compared to traditional materials. Keep in mind that a balance between filtration efficiency and oil flow must be maintained to ensure proper lubrication and engine performance.

Filter capacity

- Filter capacity refers to the number of contaminants that an oil filter can hold before it becomes clogged and requires replacement. A higher filter capacity can extend the service life of the oil filter and improve overall engine protection. When selecting an oil filter, consider filters with a larger surface area or advanced filter media that can hold more contaminants without restricting oil flow. This can help to prolong the life of the filter and maintain optimal engine performance between oil changes.

Build quality and materials

- The build quality and materials used in an oil filter can have a significant impact on its performance and durability. High-quality oil filters typically feature strong end caps, a sturdy base plate, and a reliable anti-drain back valve to ensure consistent performance and prevent oil leakage. Additionally, filters with advanced synthetic filter media can offer better filtration efficiency and capacity compared to traditional materials. When choosing an oil filter, prioritize filters with robust construction and high-quality materials to ensure that your engine receives the protection it requires for optimal performance and longevity.

Popular oil filter brands and their features

There are several popular oil filter brands on the market, each offering a range of features to suit various needs and preferences. Some well-known oil filter brands include:

- Mobil 1: Known for its high-quality synthetic oil, Mobil 1 also offers oil filters featuring advanced synthetic fiber blend media that provides excellent filtration efficiency and capacity. These filters are designed for use with synthetic oils and extended service intervals.

- FRAM: FRAM offers a variety of oil filters to suit different needs, including their popular Extra Guard, Tough Guard, and Ultra Synthetic filters. Each filter features specific media and construction designed for various levels of engine protection and performance, catering to a wide range of driving conditions and preferences.

- WIX: WIX is a well-regarded brand in the automotive filtration industry, offering high-quality oil filters with features such as wire-backed synthetic media, heavy-duty base plates, and silicone anti-drain back valves. WIX filters are known for their durability and reliable performance.

- K&N: K&N is known for its high-performance air filters but also offers a line of oil filters designed for enhanced engine protection. These filters feature synthetic media, a heavy-duty canister, and a pre-lubricated base gasket for easy installation.

- Bosch: Bosch offers a range of oil filters, including their Premium and DistancePlus lines. Bosch filters feature advanced filtration media, strong end caps, and a silicone anti-drain back valve for consistent performance and engine protection.

By considering the features and reputations of these popular oil filter brands, you can make an informed decision when selecting the right oil filter for your vehicle.

Conclusion – What Does an Oil Filter Do

Oil filters play a critical role in maintaining engine performance and overall vehicle health. They are responsible for removing contaminants and impurities from the engine oil, ensuring that it remains clean and effective in lubricating and protecting internal engine components. A well-functioning oil filter reduces friction, heat generation, and wear on critical engine parts, which in turn helps to maintain optimal engine performance, extend component life, and minimize maintenance costs. By understanding and appreciating the importance of oil filters, vehicle owners can take appropriate steps to ensure their engine remains in top condition.

Following the recommended oil filter change intervals is essential for maintaining the longevity and performance of your vehicle’s engine. By adhering to the guidelines provided by the vehicle manufacturer, you can prevent issues such as clogged filters, decreased engine performance, and potential engine damage. Additionally, regular oil filter changes can help to reduce wear and tear on engine components and minimize the risk of costly repairs. To ensure your engine remains well-protected and operates at peak performance, be diligent about following the recommended oil filter change intervals and address any potential issues as they arise.

Investing in a high-quality oil filter for your vehicle can provide numerous benefits that contribute to the overall performance and longevity of your engine. High-quality oil filters often feature advanced filtration materials and superior construction, leading to improved filtration efficiency, increased filter capacity, and enhanced durability. By using a high-quality oil filter, you can ensure that your engine is well-protected from contaminants and impurities, leading to reduced wear and tear on internal components and a longer-lasting engine. Moreover, investing in a reliable oil filter can provide peace of mind, knowing that your engine is receiving the protection it requires for optimal performance and longevity.